Just as the summer approached, we concluded the first half years’ test series in our BECCS research facility – which was the fourth in a row. It was a season full of learnings where we continued to refine the tests and developed our carbon capture technology. All that work pushed us further towards being ready to build the large-scale facility.

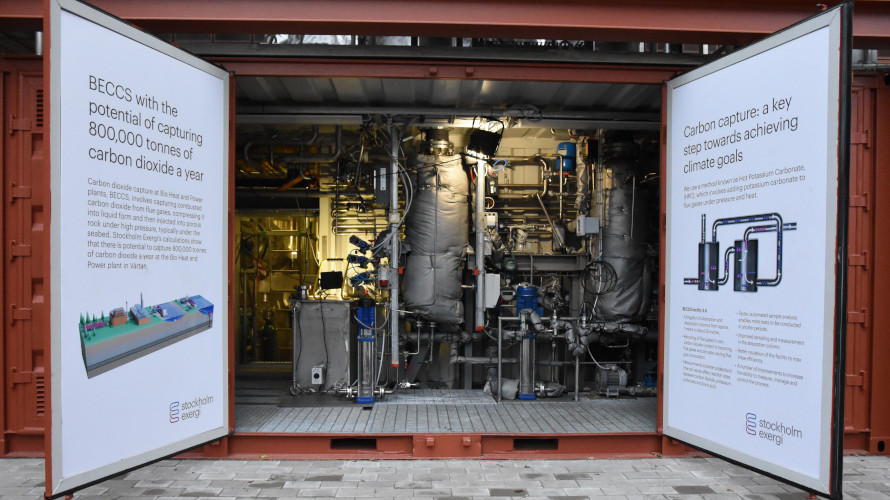

But before I get into the spring season testings, I’ll start with the biggest change of the season – at least visually. The well-known blue container turned brown and was also moved. Whether blue or brown is prettier is a matter of taste, but the new location, integrated with KVV8, is clearly a boost for the operations. The facility runs better when it is integrated. “It has run like a line”, as our operations engineer Hampus put it in terms of accessibility, and I couldn’t agree more. At the new location the facility is automatically heated, enabling a consistently high quality of steam, which provides a reliable separation in the stripping process. Hampus was hired earlier this year to work in the research facility and then later to help run the large-scale facility, which is very positive for competence and continuity. The new location of the research facility has also made it easier to train staff and welcome visitors, and more “Exergi:ers” come by to hear how things are going. Any interest in our daily operations is of course great fun!

The season started off with environmental tests. We produced extensive documentation, which is part of our application to obtain an environmental permit for the large-scale facility. Among other things, this work involved analyzing gases and condensate to ensure that we stay within the guideline values. We then submitted our permit application at the end of March.

Moreover, our work largely revolved around refining our tests and using data collection to build a dynamic model in Aspen Plus, a modeling that takes place at KTH Royal Institute of Technology, iteratively between the in-situ runs and data modeling. Our collaboration with KTH and the research group led by Professor Matthäus Bäbler is very valuable in our testing and we look forward to continuing in the upcoming autumn season.

In the research program we have done extensive work on the synthesis of gases – in fact almost every test revolved around it. And why is that so important? Well, we test different concentrations in order to understand where in the absorber reactions take place, and how the process responds to different compositions. We mix the flue gases with the gases from the absorber and the stripper to get the composition we need to generate data for the model. This is another level of quality in the testing. An example is synthesizing based on the theoretical outcome of mixing oxygen in the combustion air, which gives a higher proportion of CO2 in the flue gas and thus more efficient separation.

Just like previous seasons, patient work is required to get all the data that forms the foundation of the development. Well rested from the summer vacation we are now eager to continue our work during the autumn. As I said, it is the large-scale facility that is our ultimate goal!

Erik Dahlén