The Stockholm Exergi KVV8 facility is Europe’s largest biomass-based Combined Heat and Power plant. CO2 that was previously circulating between the atmosphere and trees will now be withdrawn from the atmosphere, directly contributing to cooling of the atmosphere.

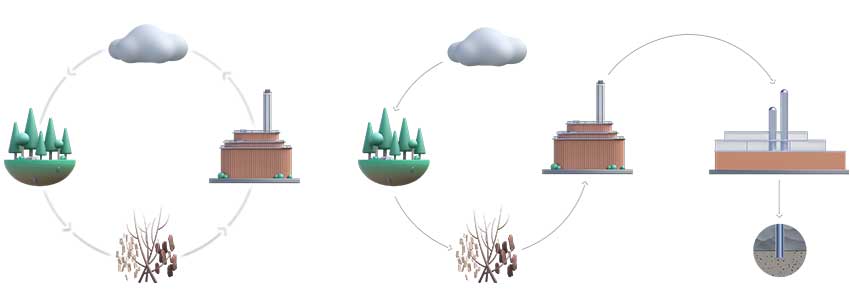

The Stockholm Exergi KVV8 facility is Europe’s largest biomass-based Combined Heat and Power plant. By capturing the plant’s biogenic carbon dioxide emissions and permanently storing it in the geosphere, the carbon flow is reversed, and a carbon sink is formed. CO2 that was previously circulating between the atmosphere and trees will now be withdrawn from the atmosphere, directly contributing to cooling of the atmosphere.

Flow-diagrams showing the natural cycle for a bio-fuelled CHP-plant (left) with net zero emissions of carbon dioxide, and the natural cycle when completed with capture and storage (right) leading to negative emission of carbon dioxide

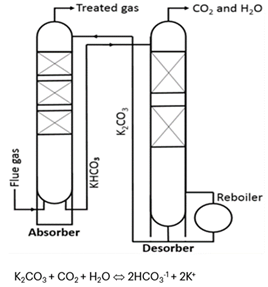

To accomplish this, the CO2 in the flue gases of the bio-energy CHP must be captured. Based on careful assessment and previous experience of carbon capture, Stockholm Exergi has chosen to work with the well-proven Hot Potassium Carbonate technology.

The flue gas with the carbon dioxide meets a solvent liquid, which mostly consists of water and potassium carbonate. Potassium carbonate is a harmless ionic compound (salt) that is also used as a pH adjuster in food.

Pressurized potassium carbonate reacts with CO2 and H2O, which forms potassium bicarbonate (i.e. baking powder). When the potassium bicarbonate pressure is lowered, the reaction goes in the opposite direction, releasing CO2 and H2O. In this way, the process works continuously and the CO2 can be separated and captured.

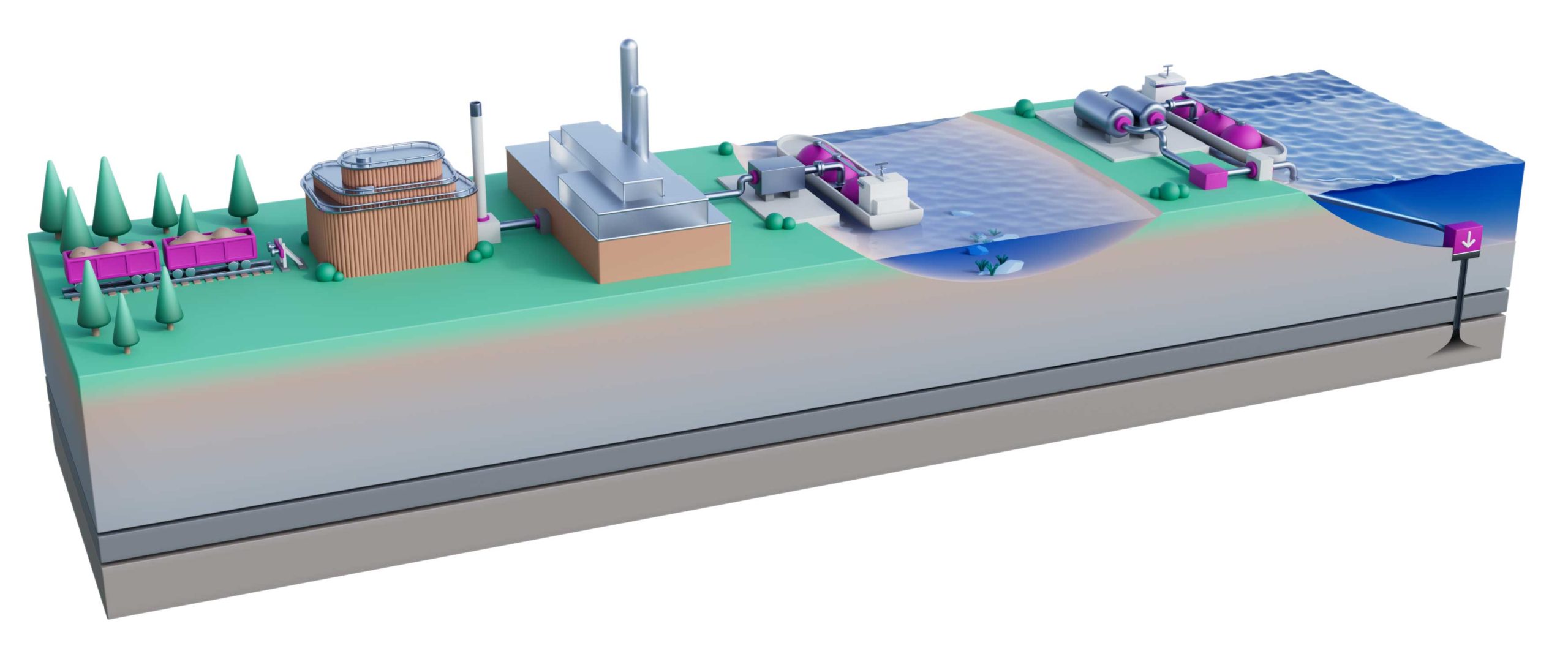

The KVV8 plant, the HPC installation and shipment to geological storage.

After the capture process, the biogenic CO2 will be purified and then liquefied. The purpose of the liquefication is to make the transportation more efficient, since liquified CO2 requires much less volume than CO2 in gas form. The pressure can, typically, be 7 bar, with the temperature 50 degrees Celsius below zero. After liquefaction the carbon dioxide is stored in buffer-tanks, before being shipped to the final storage site.

In the capture and liquefaction processes, excess heat is released, which we reuse in Stockholm’s district heating network.

The final storage site is where the CO2 will reside for thousands of years. Already in 2005 did IPCC conclude that geologically stored CO2 had a probability of 99% or more to remain in storage after 1 000 years*.

To achieve this level of permanence, the site must fulfil the following criteria:

Based on a long experience of working with CO2 geological storage since 1995, there are several sites around the North Sea which can fullfill these criteria. More information on geological storage is available at the European research network CO2 GeoNet.